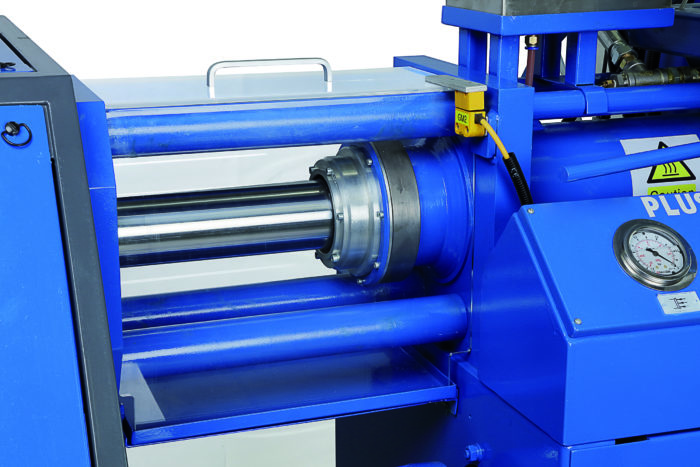

ECO-NX Smart Preformers

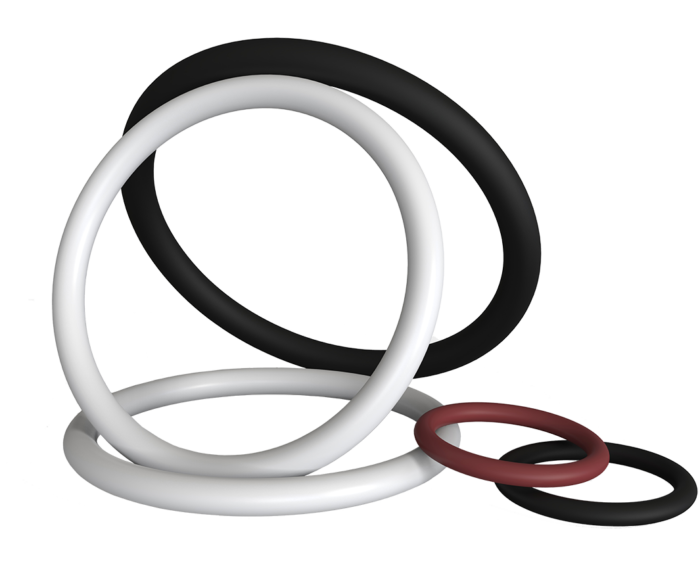

The range is specifically designed for the accurate and efficient processing of rubber and synthetic polymer compounds across multiple industries.

It is a safe, operator-friendly and versatile processing system ensuring most types of compounds can be processed to produce consistent and accurate products with minimal material wastage.

- Large selection of batch sizes (1-80 litres)

- High-pressure options

- 400 cuts per minute speed (800 cpm option)

- The proven Barwell scales feedback system for automatic weight adjustment to ensure rubber blank control

- Accuracy of up to +/- 1% by volume

- Barcode reader

- Extended centre for easy cleaning

- Reversing conveyor

- Large 9” (230mm) widescreen Omron colour touch-screen operator interface

- Quick product set-up due to a 5000 product database and an autocycle option